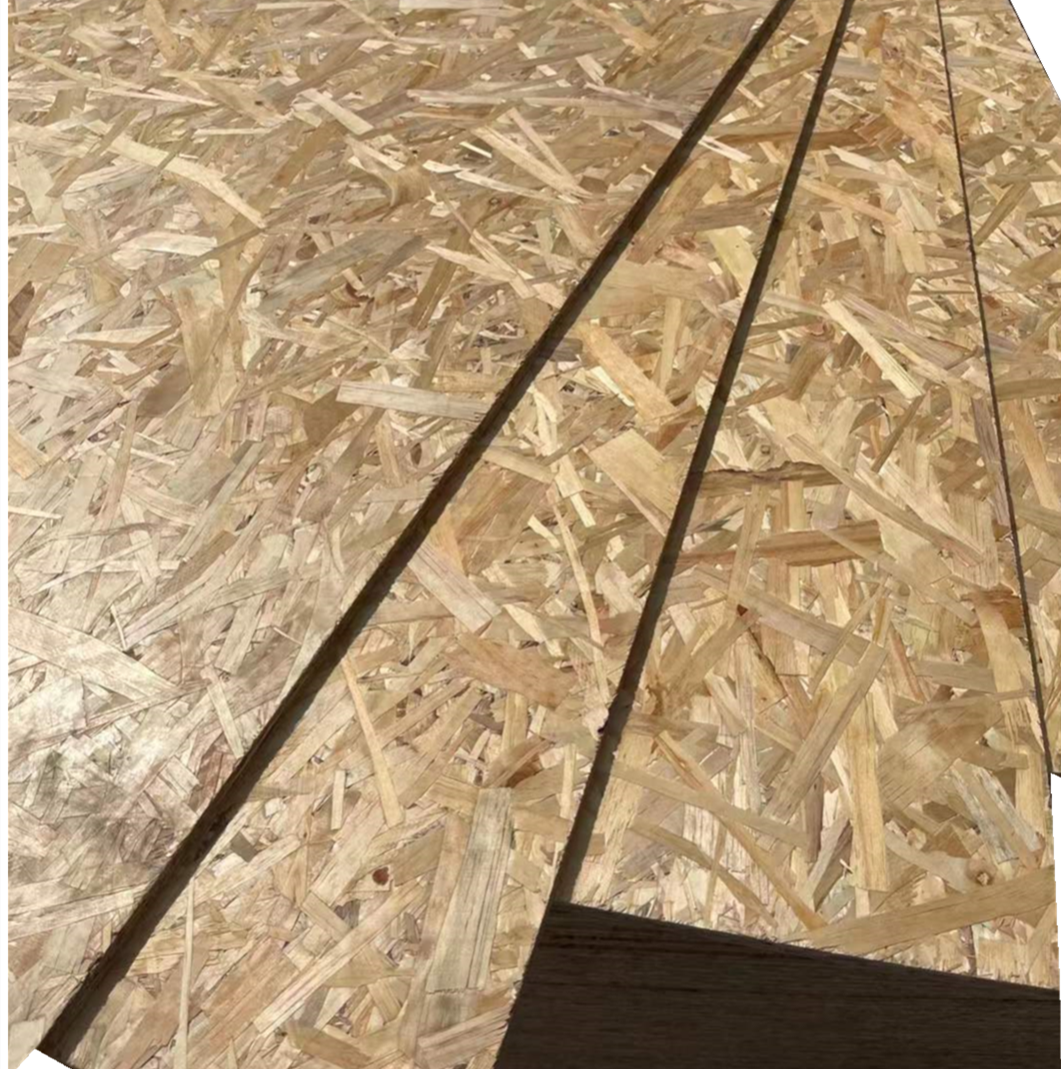

1 Exposure to the sun, after rain, often encounters the sun, which accelerates the deformation of the template, another factor, but also the main reason for the delamination of the corners.

2 The problem of raw materials, the quality of watering, and the pressure that the template bears during the hot pressing process are also the main reasons that directly lead to the delamination of the template in the later stage.

3 After contacting with cement, concrete and other corrosive substances, coupled with no technical maintenance after removal, it is easy to cause the formwork to be corroded.

4 In the process of construction and installation, the technical level of workers is difficult to be unified, which is also an important factor. Random sawing, violent demolding, hole drilling, and violent beating are more common. There is no priority at all for an optimized design of the template, or numbering.

5 The contact time between the formwork and the concrete is relatively long, and the adhesion is too tight, which makes it difficult to remove the formwork. The resulting template layer is torn.

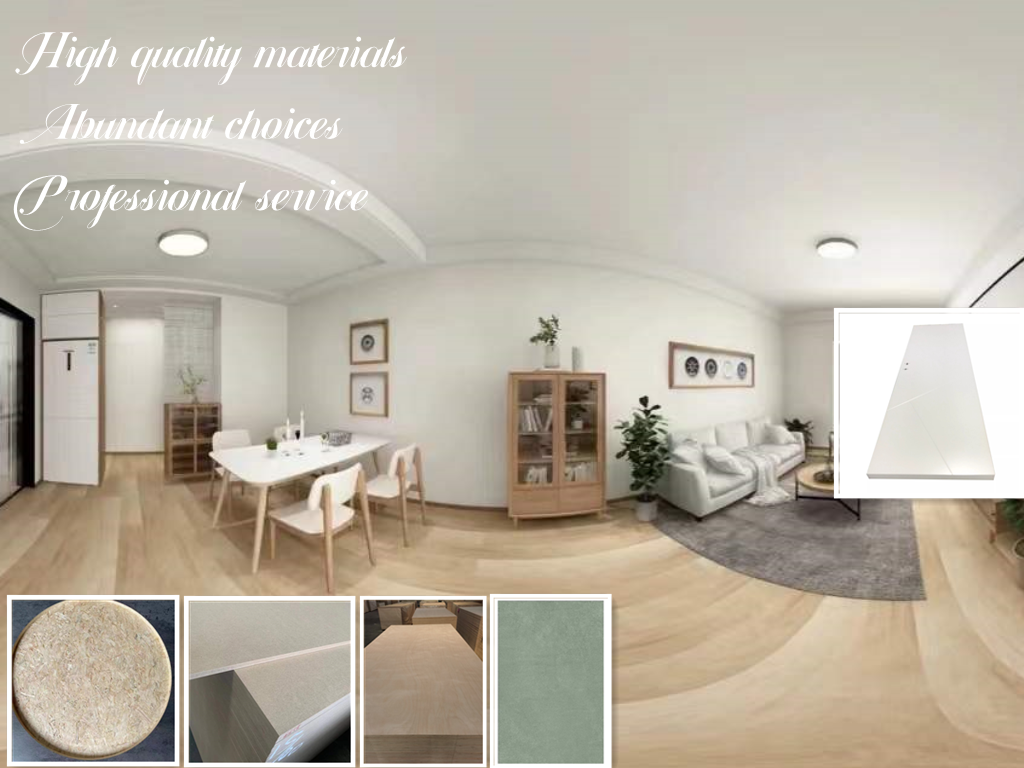

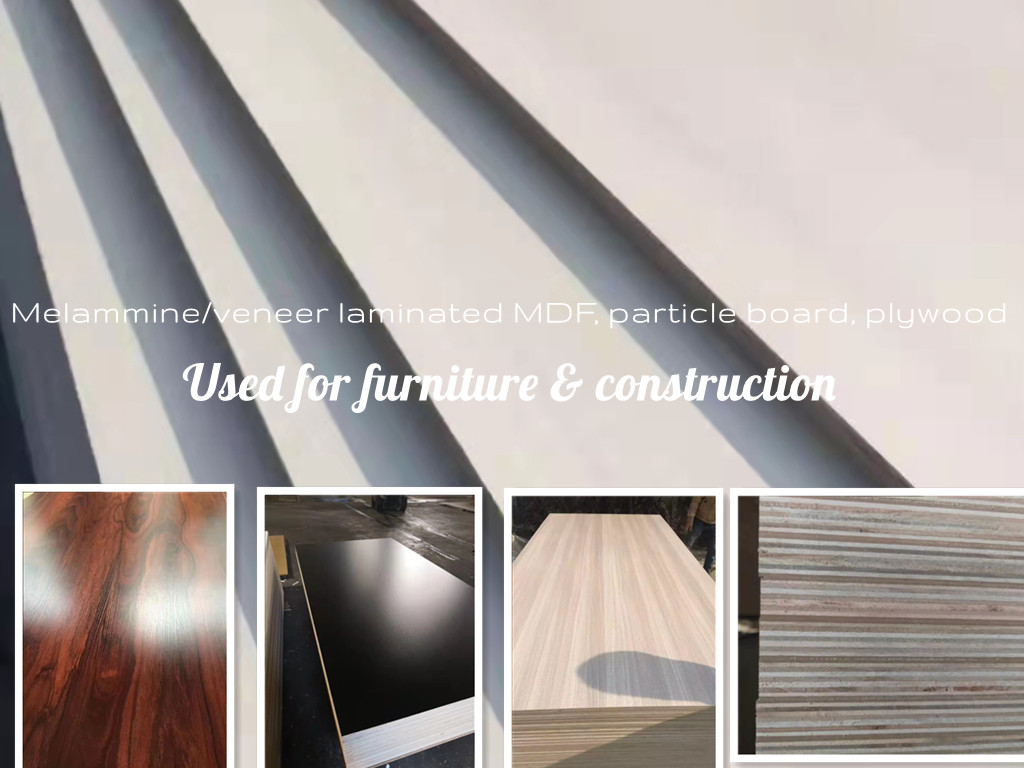

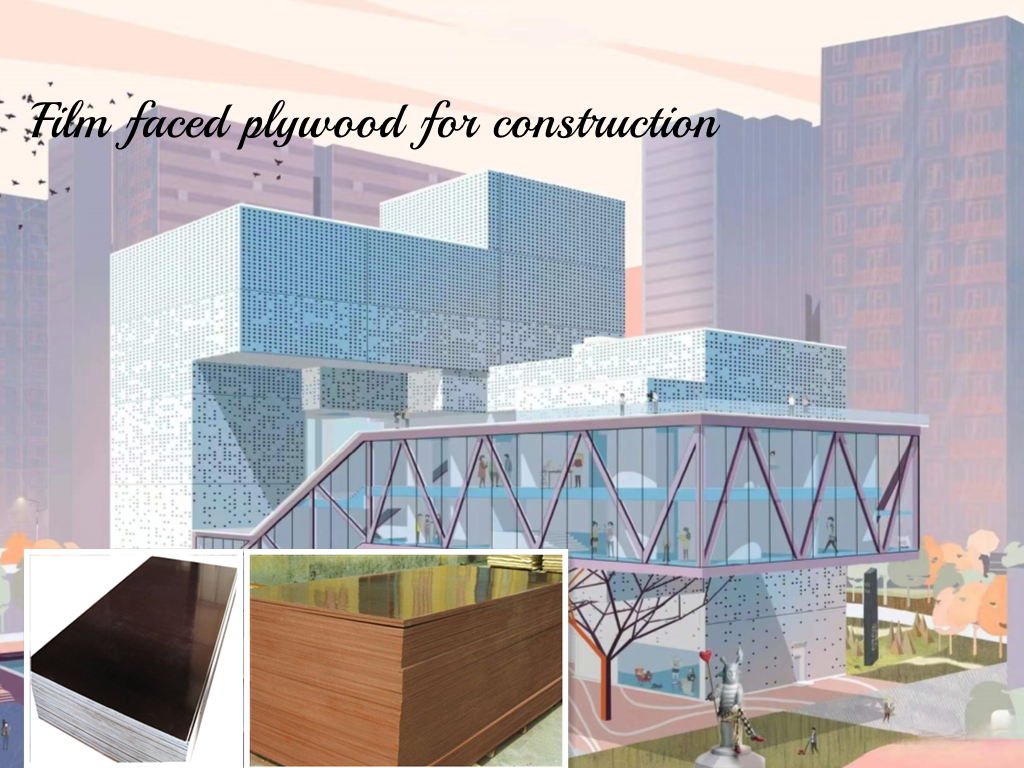

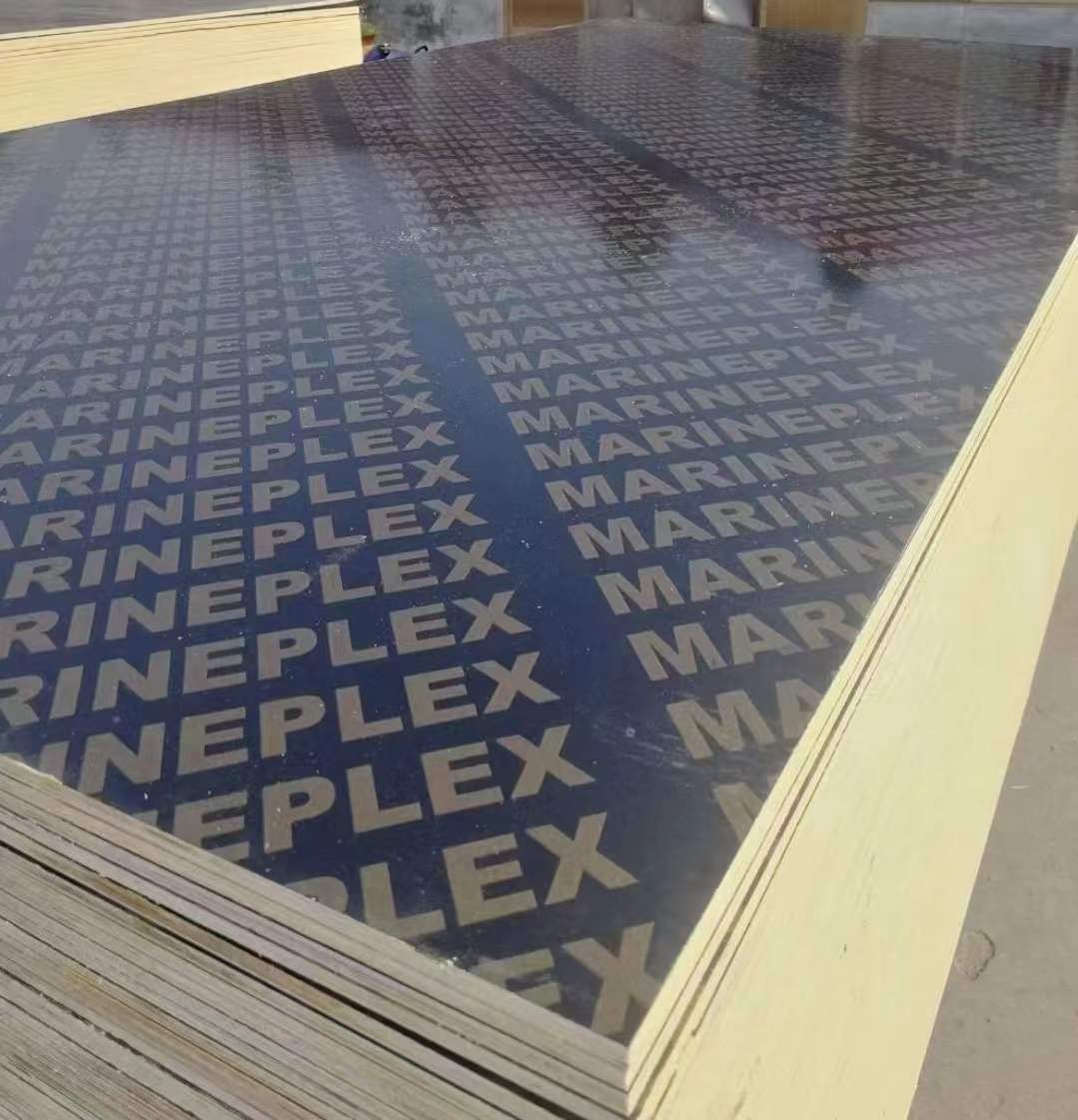

ZMADTO Plywood Co.Ltd is focus on construction plywood & wood formwork product. Our factory was established in 1993 and covers an area of 240,000 square meters with an average daily output of more 30,000 pcs plywood. Besides, the factory has more than 200 advanced equipment. After years of continuous development, it has become a leading company in the international wood formwork industry and exported to more than 20 countries around the world.